Mikrosphere – it’s worth knowing:

|

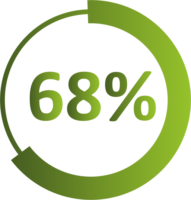

thermal resistance is increased by this value |

|

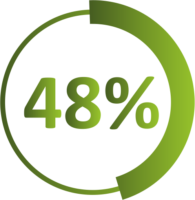

water absorbability is decreased by this value |

|

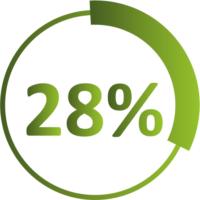

heat transfer coefficient is decreased by this value |

|

UV radiation absorption is decreased by this value |

|

impact resistance of render is increased by this value |

|

1 m² of render surface area is cheaper by this value |

Mitech Microsphere Technology:

DEFINITELY IMPROVES APPLICATION

DEFINITELY IMPROVES APPLICATION

Microsphere works the same way as bearing balls, allowing to easily and freely mix render aggregate. The use of lightweight, spherical filler improves installation, which facilitates work and render application.

INCREASES PERFORMANCE

INCREASES PERFORMANCE

Easy and light render application translates into lower material consumption by approx. 5%

LOWER ABSORBABILITY

LOWER ABSORBABILITY

Microsphere features a thermal resistance to low and high temperatures. Low absorbability results in lower render water absorption, which improves a resistance to low temperatures (frost). The use of microsphere in renders extends product life especially under variable operation conditions.

IMPROVES INSULATION PROPERTIES

IMPROVES INSULATION PROPERTIES

Very good performance properties of the microsphere, its low apparent density, low heat transfer coefficient allow for creating a link network inside the render providing a protective layer to reduce the heat transfer coefficient.

RESISTANCE TO UV RADIATION

RESISTANCE TO UV RADIATION

Thanks to gas filling the microsphere acts as a thermal insulation when exposed to high temperatures. It allows to reduce façade exposure to UV radiation especially if dark colours are used, HWB<25%. It reduces the destructive impact of sunlight.

MECHANICAL RESISTANCE

MECHANICAL RESISTANCE

High mechanical resistance of microspheres translates into better mechanical resistance of the microsphere containing render.

REDUCES BIOLOGICAL CONTAMINATION

REDUCES BIOLOGICAL CONTAMINATION

Low render absorbability, negligible porosity of microsphere walls and the support provided by a coat protective agent reduce the growth of algae and fungi.

POSITIVE IMPACT ON NATURAL ENVIRONMENT

POSITIVE IMPACT ON NATURAL ENVIRONMENT

By using the advanced technologies of hard coal burning and the processing of volatile ashes generated by its combustion, the microsphere being a side product of the process is an exclusive material recommended for industrial use with no negative impact on the natural environment.