- resistant to weather factors

- It does not spread fire

- flexible and durable

- simple and easy to apply

Frost-resistance

Frost-resistance Products available in Microsphere technology

Products available in Microsphere technology Coating resistant to organic growth of algae and fungi

Coating resistant to organic growth of algae and fungi Products available in VIP Collection colour palette

Products available in VIP Collection colour palette Easy to apply

Easy to apply Resistance to weather factors

Resistance to weather factors European technical assessment

European technical assessment- Application

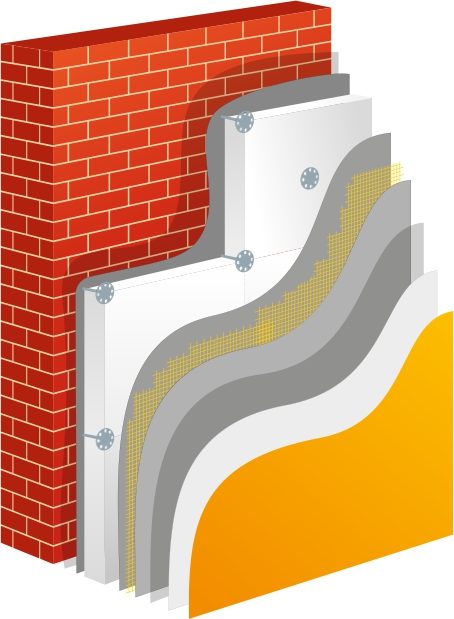

MITECH building thermal insulation system is a complex external thermal insulation composite system (ETICS) based on foamed polystyrene as the insulation layer. It is used to apply external wall insulation system for existing buildings and newly erected ones by using foamed polystyrene boards as insulation layers in traditional and energy-saving construction. It can be used on raw and rendered walls made of bricks, concrete, ceramic blocks, cellular concrete, cement hollow blocks. The system can be used while using the maximum foamed polystyrene thickness board of up to 25 cm and the maximum building height of up to 25 m. The MITECH system meets the European Technical Assessment (ETA) and is allowed for use within the whole European Union. The properties of external thermal insulation composite system (ETICS) make it possible to limit heat losses, reduce heating costs, remove thermal bridging and improve the aesthetics of the insulated façade. The technology of Mitech system consists of the following steps: installing a foamed polystyrene layer to the external wall surface, making a reinforcing layer with immersed glass-fibre mesh and applying a primer and a thin-layer render. When combined with a mineral render, a façade paint should be used.

SYSTEM COMPONENTS

Product Consumption per m² MITECH KS adhesive used to install foamed polystyrene boards 4.0-5.0 kg MITECH KO universal adhesive for foamed polystyrene-based external thermal insulation composite system (ETICS) 3.5-4.0 kg Glass fibre mesh 145 g 1.15 m² Mechanical links 4 pieces MITECH FX or GSK, GSL, GSI primer agent under render 0.28 kg MITECH TAK or TSK, TSL, TSISI, TSI thin-layer renders with Microsphere 2.0-2.5 kg MITECH TMB mineral render 2.0-2.5 kg SYSTEM PROPERTIES

Feature Value Water absorbability after 24 hours < 0.5 kg/m² Watertightness meets the requirements Reaction to fire (according to Etag 004/ En 13501-1+A1) A2-s1,d0 Resistance to mechanical damage with acrylic, siloxane, silicone-silicate and silicone render Category II with mineral and silicate render Category III vapour permeability Sd from 0.17 to 0.44 m - Download